Beyond the Blueprint: Unveiling Hidden Gems in Top Plywood Boat Plans

Building a boat from plywood is a rewarding challenge, blending woodworking skill with the thrill of nautical adventure. While countless plans are available, many overlook crucial factors that can significantly impact the success and enjoyment of the project. This review delves beyond the standard plan features, exploring often-overlooked aspects to help you navigate the world of DIY plywood boat building with fresh eyes.

The Unsung Heroes: Material Selection and its Impact

Most plans simply state "marine-grade plywood." But is that enough? Let's dig deeper.

Q: What's the real difference between various marine ply grades?

A: The grade dictates the quality and number of knots. A higher grade (like "A-A" or "A-B") means fewer voids, leading to a stronger, more water-resistant hull. But it also significantly impacts cost. Consider the intended use: a sheltered lake boat might tolerate a slightly lower grade, whereas an ocean-going vessel demands premium material. This isn't usually explicitly addressed in plans but is crucial.

Q: How does the type of adhesive influence the lifespan and build?

A: Many plans assume standard exterior-grade wood glue. But research shows that epoxy adhesives offer superior water resistance and strength, particularly in demanding applications. The added cost is often justified by the improved longevity and overall structural integrity of the finished boat. While this might not be discussed in the plan itself, it's a powerful upgrade.

Beyond the Lines: Creative Design Tweaks and Customization

While following a plan is essential, don't be afraid to inject your creativity.

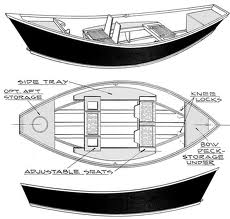

Q: Can I modify existing plans to suit my needs and skills?

A: Absolutely! Many plans allow for customization. Consider your skill level: if you're a beginner, simplifying complex curves or reducing the number of parts might be beneficial. Experienced builders might explore adding features like a custom cockpit layout or integrated storage solutions. This is where your personal woodworking expertise truly shines.

Q: How can I incorporate sustainable materials and practices?

A: Explore using reclaimed or sustainably sourced plywood. Consider eco-friendly finishes like natural oils or water-based paints instead of harsh chemical-laden varnishes. These choices enhance the environmental friendliness of your project, a growing trend among boat builders. Many resources, like the Forest Stewardship Council (FSC), can guide you to responsible lumber.

The Unexpected Challenges: Real-World Stories and Solutions

Let's learn from others' experiences.

Story 1: John, a novice builder, chose a complex design for his first boat. He struggled with intricate curves and ended up frustrated and overwhelmed. The lesson? Start with a simpler plan, gaining confidence before tackling ambitious projects.

Story 2: Mary underestimated the time required for finishing. Her beautifully crafted hull sat unfinished for months, losing its luster and resilience to weathering. The takeaway? Factor in ample time for finishing and allow for unexpected delays.

Conclusion: Building Smarter, Not Just Harder

Choosing the right plywood boat plans is only the beginning. By considering factors like material selection, creative customization, and learning from real-world experiences, you can transform your project from a simple construction exercise into a deeply rewarding and fulfilling journey. Don't just build a boat; build a masterpiece that reflects your skills and unique vision.

Further Resources:

- Forest Stewardship Council (FSC): www.fsc.org

- Boatbuilding websites and forums: Search for online communities dedicated to plywood boat building for valuable insights and advice.