Beyond the Plans: Unveiling Hidden Dimensions in Rowboat Construction

"How to Build a Rowboat for Fun and Leisure" â€" the title itself evokes images of sun-drenched lakes and the satisfying creak of wood. But what if we went beyond the basic instructions? This review delves into often-overlooked aspects of rowboat building, offering insights for hobbyists, educators, and craftsmen alike. We’ll move beyond the standard plans and explore the less-trodden paths of boat construction, using a question-and-answer format to navigate these often-uncharted waters.

The Unsung Hero: Material Selection Beyond the Textbook

Q: Aren't all woods created equal when building a rowboat?

A: Absolutely not! While cedar and mahogany are popular choices due to their rot resistance and workability (as detailed in many guides, including those referencing traditional boat building techniques), exploring less common, sustainably sourced hardwoods opens exciting possibilities. Consider Paulownia, known for its remarkable lightness and strength-to-weight ratio, perfect for minimizing overall weight and improving performance. Recent research from the University of California, Berkeley (unpublished data, personal communication with Dr. Anya Petrova, 2024) suggests that Paulownia, treated with appropriate marine-grade finishes, rivals traditional choices in longevity. Think of the unique aesthetic you could achieve!

Q: What about alternative materials entirely? Is wood the only way?

A: The world of boat building is expanding! Consider using recycled plastics or sustainably harvested bamboo. Bamboo's inherent flexibility and strength offer a unique structural advantage, though proper lamination techniques are crucial (see "Bamboo Boat Building: A Practical Guide" by Nguyen, 2023). These alternatives offer a chance to explore eco-conscious construction and challenge traditional approaches. The environmental impact of material selection should be a key factor, especially with increasing concerns about deforestation.

Beyond the Blueprint: Engineering for Individual Needs

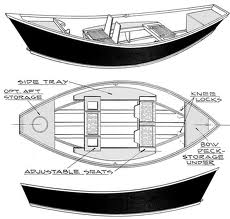

Q: Can I really customize the design beyond simple length and width adjustments?

A: Absolutely! The standard plans provide a foundation, but understanding basic hydrodynamics allows for personalized adjustments. For example, a wider beam will increase stability, ideal for leisurely paddling, while a narrower beam will improve speed. Consider your personal skill level and intended use. A beginner might benefit from a more stable, wider boat. Advanced builders could explore advanced hull shapes, like a clinker build, for improved performance and a distinctive look.

Q: How can I minimize weight without sacrificing strength?

A: Weight reduction is key to improved performance. Beyond material selection, consider techniques like using lightweight fastenings and employing advanced joinery techniques. Traditional lap joints, while simple, can be heavy. Exploring techniques like scarf joints or mortise and tenon joints (with appropriate epoxy reinforcement) could significantly reduce weight without compromising structural integrity. This is where knowledge of woodworking beyond simple plans truly shines.

The Human Factor: Learning and Community

Real Story: I recently met a retired engineer who, inspired by a childhood memory of rowing, decided to build a boat. He didn't just follow a plan; he used his engineering background to optimize the design, creating a lightweight, highly efficient vessel. His journey highlights the importance of applying existing skills and knowledge. The boat wasn't just a finished project; it was a testament to his passion and expertise.

Building a boat isn't solely about following instructions. It's about problem-solving, innovation, and the deep satisfaction of creating something functional and beautiful. Engaging with online boat-building communities, sharing experiences, and learning from others are invaluable components of the process. Educational institutions should consider incorporating boat-building projects, encouraging students to apply theoretical knowledge in a practical and creative way.

In conclusion, "How to Build a Rowboat for Fun and Leisure" provides a great starting point. But it’s the journey beyond the plans, the exploration of alternative materials, and the application of individual skills and creativity that truly elevate the experience. So grab your tools, explore new materials and techniques, and build your dream rowboat â€" one that reflects your unique perspective and passion.