Plywood Boat Plans: Beyond the Blueprint â€" Unlocking Unexpected Potential

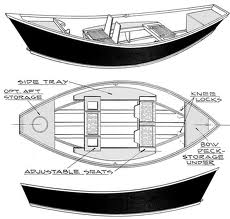

Building a boat from plywood is a rewarding challenge, a blend of woodworking precision and nautical dreaming. But beyond the readily available plans and tutorials, lies a wealth of untapped potential. This article dives deeper, exploring often-overlooked aspects of plywood boat construction, offering fresh perspectives for hobbyists, professionals, and anyone captivated by the allure of building their own vessel.

The Unsung Hero: Plywood Selection â€" More Than Just Grade

We all know about marine-grade plywood. But have you considered the *subtle* variations within that grade? Different manufacturers employ varying glue types and wood species. The seemingly minor differences in these factors can significantly impact the boat's longevity and performance.

Q: How can I choose the *best* plywood for my project?

A: It's not a one-size-fits-all answer. Research specific manufacturers. Look for independent tests assessing their plywood's resistance to delamination under various conditions (moisture, stress, etc.). Consider contacting a marine supply expert; they often have access to data not readily available online. Don't just focus on the grade; explore the *specific properties* of the plywood from your chosen supplier.

Beyond the Plans: Sustainable and Innovative Materials

Traditional plywood boat building often sticks to the tried and tested. However, the world of sustainable and innovative materials is constantly evolving. Are we missing opportunities for more environmentally friendly and potentially stronger builds?

Q: Can we integrate recycled or reclaimed materials into plywood boat construction?

A: Absolutely! Consider using reclaimed lumber for structural elements not directly exposed to water (like bulkheads or internal framing). Explore sustainably harvested plywood options certified by organizations like the Forest Stewardship Council (FSC). This isn't just about environmental responsibility; it can also lead to unique aesthetic qualities in your boat.

The Forgotten Factor: Design Optimization Through Simulation

Most boat plans are based on proven designs, but what about pushing those boundaries? Modern computational fluid dynamics (CFD) and finite element analysis (FEA) software can provide invaluable insights into hull performance and structural integrity. These are tools often overlooked by hobbyists, but they can lead to significant improvements.

Q: How can I leverage technology for better boat design?

A: Many free or relatively inexpensive software packages are available for simple hull design simulations. Even basic analysis can highlight potential weaknesses in a chosen plan, allowing for proactive adjustments. This is a significant step beyond simply following a pre-existing blueprint.

Real-World Example: The "Unexpected" Success Story

A recent project by a university woodworking program provides a compelling example. Students, using readily available plywood and incorporating recycled plastic composite materials in non-structural components, built a surprisingly efficient and durable small sailboat. Their design, heavily reliant on CFD analysis, minimized drag and maximized stability, exceeding initial expectations. This demonstrates how a creative, data-driven approach can yield exceptional results even with limited resources.

Conclusion: Building a plywood boat isn't just about following instructions. It's about exploring, innovating, and pushing the boundaries of what's possible. By considering plywood selection, sustainable materials, and advanced design techniques, you can elevate your project from a simple build to a truly unique and rewarding experience.